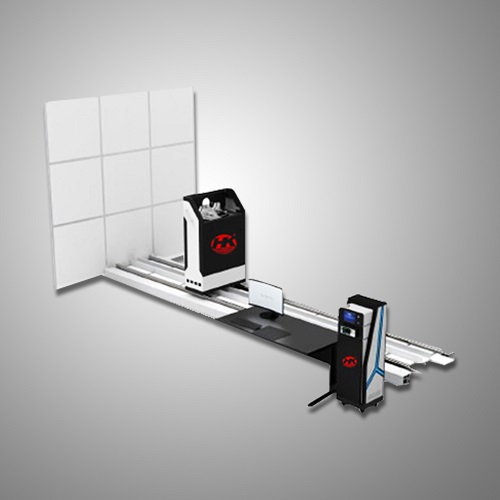

Dispositivo de verificación de nivel de líquido con método de simulación HK-7020

Marca : HKOrigen del producto : Porcelana

El tiempo de entrega : dentro de los 30 días posteriores a la recepción del pago completo de TT

Capacidad de suministro : 100 juegos/mes

El dispositivo de verificación de medidores de nivel de líquido HK-7020 con método de simulación cumple con los requisitos del Reglamento de Verificación JJG 971. Es un dispositivo especializado para la verificación metrológica de instrumentos de nivel de líquido sin contacto. Integra el sistema de control principal, la pista lineal, el carro de prueba, el objetivo de reflexión, el sistema de adquisición eléctrica y un software de control totalmente automático. El dispositivo se basa en el sistema de control para un control preciso del nivel de líquido y en el sistema de medición para una medición precisa del nivel de líquido. Combinado con un software específico, realiza pruebas totalmente automáticas e incluso puede generar e imprimir certificados de verificación, cumpliendo con los requisitos de prueba de ciclo completo. Se aplica ampliamente en institutos de metrología e investigación, fabricantes de medidores de nivel de líquido y laboratorios de calibración de diversas industrias.

Overview

Functional Features

Technical Parameters

Packaging & Shipping

1 How to deliver?

We can send by Express or by Air. Also we have best transportation solution for DHL, FEDEX, UPS,TNT faster and cheaper

2 What if it broken during transport?

Please do not worry, we do standard export package.

We have 12 months warranty, if it broken during transport, we can change a new one for you. If it is broken after 12 months, we can supply you a new one at a cost price.

FAQ

1. Why choose us?

Low price:

We are end manufacturer instead of trader or dealer, saving a lot of medium cost, cutting the prices factually and saving money for customers.

High quality:

Our company focuses on product quality. We equip professional research and development team.

Good service:

We could provide product catalog and user manual to customer during inquiry stage. We will offer the installation and operation video, debug video and maintaining videoto our customer before Ex-work. Following link is the video address which is for our previous customer:

https://www.youtube.com/channel/UC4NDJI_tKsJIuaixCMDQF4w

We offer fast delivery and secure packing. We provide one year guarantee and long term spare parts supply at cost price.

2. How can I choose the suitable one?

We design and manufacture our testers based on ASTM, IP, ISO standards, so user may tell the exact standard or test method to us, and then we can offer our solution.

3. How can I pay?

We accept many payment terms, such as T/T, L/C, Western Union, PayPal, and money gram and so on.

4. When I receive it after pay?

Normally, we have testers in our stock, if not, we can deliver within 5-7 days, please contact us to check transport time and charge to your address.

5. What should I do if I do not know how to use?

Please do not worry, manual user will be sent together, also we can offer Operation and installation video, you can also contact us with more technological support.

6. What should I do if some parts broken?

Please do not worry, we have 12 months warranty except accessories, you can also buy parts from us after 12months.

7. Can I order OEM/ ODM services?

YES, product can be customized.